When it comes to backpacks, there are a variety of backpack materials to choose from. A lot of the options available on the market are made out of nylon, polyester, canvas, leather, and specialized fabrics like ballistic nylon. Each material has its advantages and disadvantages when it comes to durability, water resistance, weight, comfort, and style.

Primary Materials Used in Backpacks

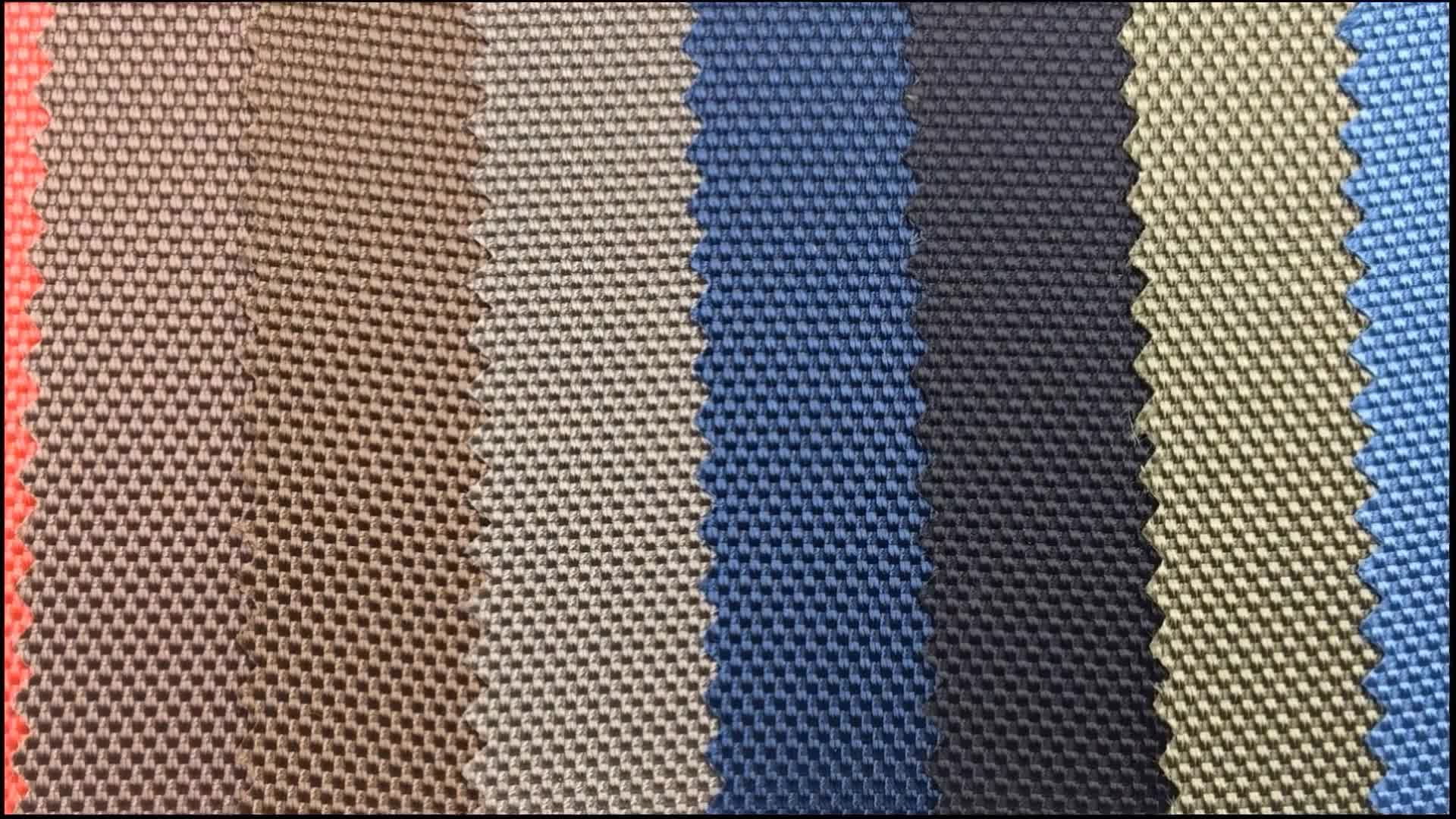

The outer fabric is what gives a backpack its durability, look, and feel. Most backpacks are made using one primary material for the majority of the pack. Secondary fabrics are often used for highlights, accents, or heavy wear areas. Here are some of the top materials used to make modern backpacks:

Nylon

One of the most popular backpack materials, Nylon, is known for its high strength, abrasion resistance, flexibility, and water-resistant properties. The nylon fibers are woven tightly together to create a strong & lightweight fabric that dries quickly and can withstand daily wear and tear, making it an excellent choice for those seeking a long-lasting backpack.

However, one of the drawbacks of backpack nylon is its susceptibility to UV damage and color fading over time. Backpack Nylon has multiple types which include Denier, Ripstop Nylon, Ballistic Nylon, Recycled Nylon, and Cordura.

Polyester

Polyester is the second most widely used synthetic material in the construction of a backpack after nylon and is comparably less expensive with a lower strength-to-weight ratio. Polyester is inherently somewhat waterproof, quick-drying, and has great UV resistance. Polyester tends to be more fade-resistant than nylon when dyed.

Cotton Canvas

Cotton Canvas is one of the oldest natural backpack materials. This fabric is made from woven cotton fibers, creating a thick, heavy, durable, and breathable texture. Cotton backpacks have high abrasion resistance, but the material will absorb moisture and take longer to dry when wet.

Uncoated backpacks can become dirty easily therefore, some canvas backpacks are waxed or treated with polyurethane for water resistance.

Cordura

Cordura is a branded type of textured nylon fabric. It is highly abrasion resistant while remaining lightweight. The dense weave of this material makes Cordura extremely durable and tear-resistant with good water-repelling properties.

Cordura tends to be more expensive than standard nylon or polyester, so it’s normally used selectively in backpacks, you will mostly see this backpack fabric being used in military backpacks and tactical backpacks.

Polyester Pack Cloth

Pack cloth is a lightweight, inexpensive, waterproof polyester fabric. It shares many similarities with regular polyester but has a more pronounced woven texture. Pack cloth is quite versatile – it’s water resistant, easy to clean, and works well for school backpacks, gym bags, and weekenders.

The main advantage of pack cloth is that it’s very affordable while being reasonably durable. It won’t handle the roughest adventures as well as Cordura or ballistic nylon but makes for a cost-effective choice for basic backpacks and shoulder bags.

PVC (Poly Vinyl Chloride)

PVC fabric treated with polyurethane creates a synthetic leather substitute. PVC is very lightweight and waterproof. It’s also easy to clean by just wiping down the surface.

PVC is frequently used on ultra-affordable backpacks and low-cost school bags. While very inexpensive, PVC does not breathe well and tends to degrade faster than fabrics like nylon or canvas when faced with abrasion, sunlight, and environmental factors.

Ripstop Nylon

Ripstop nylon gets its name from the special reinforcing woven into the fabric. Thin cross threads are interwoven at regular intervals in a grid pattern (crosshatching). This makes Ripstop tear strength high while maintaining the lightweight flexibility of nylon.

Ripstop is also water resistant but not fully waterproof. A DWR coating is sometimes added for enhanced weather protection.

Leather

Leather is a less common natural backpack material that develops a lovely patina over time. Leather is extremely durable and partially water resistant. Prolonged water exposure may result in leather backpacks becoming completely wet.

The main drawbacks of leather are the high cost and heavy weight. Leather backpacks also require more care. To clean, simply wipe down with a moist cloth. Condition monthly using a leather care product. While beautiful, keep in mind leather backpacks do take some maintenance.

Specialty Backpack Materials for Enhanced Features

In addition to the primary shell fabric, backpack manufacturers often use supplemental fabrics to improve durability, weather resistance, comfort, and style:

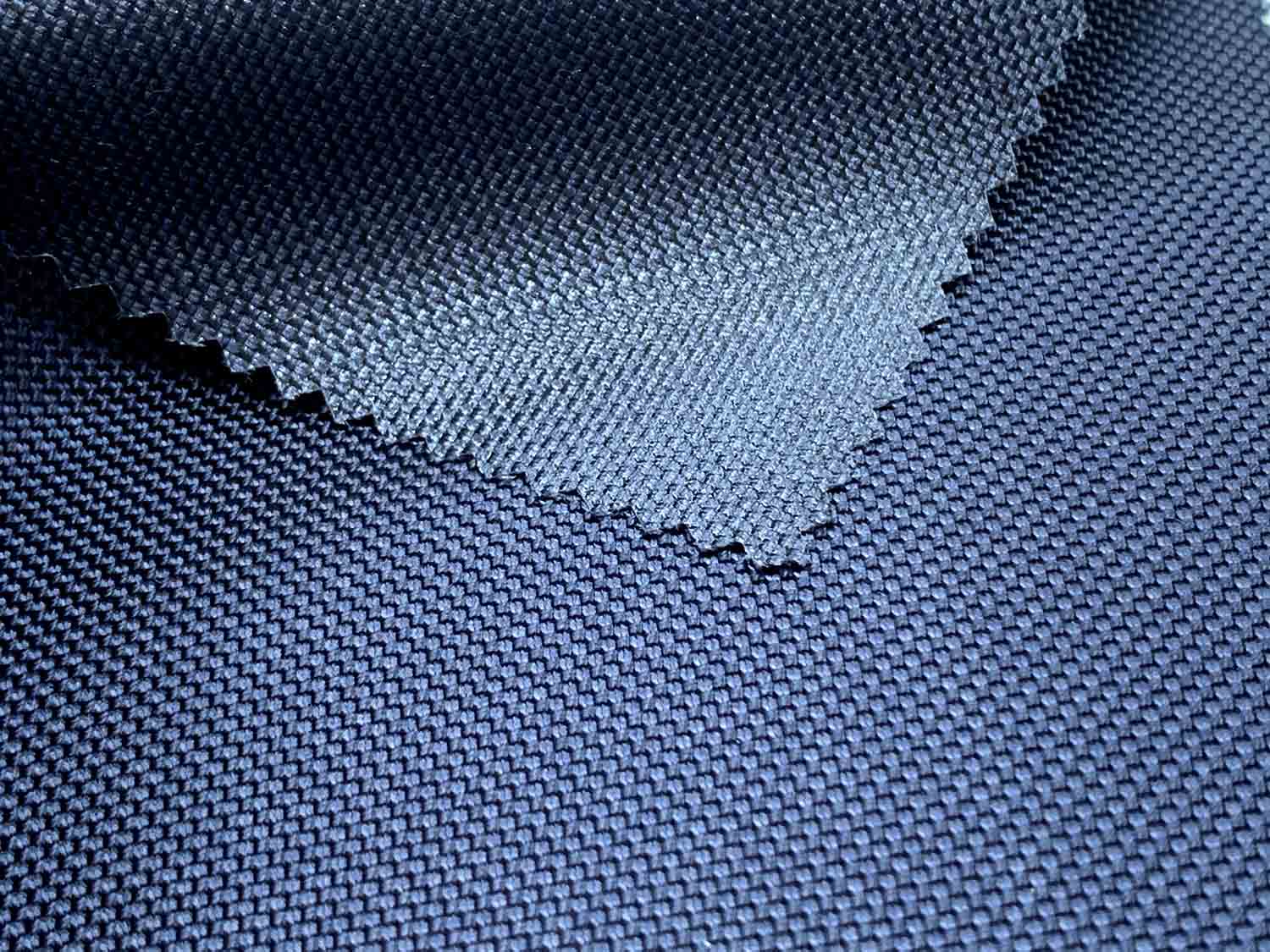

Ballistic Nylon

Developed by DuPont Corporation, Ballistic nylon is even tougher than regular nylon and has excellent tear strength and abrasion resistance. It’s constructed of high-denier interwoven nylon fibers specially coated to maintain flexibility. Ballistic nylon is frequently used to make ultra-durable travel packs.

Oxford Nylon

Similar to pack cloth, Oxford nylon has a coarser woven texture with more cross threads per inch. This creates enhanced tear and abrasion resistance. Oxford makes for rugged yet affordable backpacks. Its different specifications are 210D nylon oxford cloth, 420D nylon oxford cloth, 840D nylon oxford cloth, 1680D nylon oxford cloth, 500D nylon oxford cloth, and 1000D nylon oxford cloth.

TPE (Thermoplastic Polyurethane)

Combining the properties of rubber and plastic TPE resembles leather but contains no animal products. It repels water well while being very light. TPE adds durability and weather resistance with a leather-like look.

EVA (Ethylene-vinyl Acetate)

EVA foam is pliable with good shock-absorbing qualities, it is fully recyclable and non-toxic. It’s often used to provide padding on straps, backs, and inside laptop sleeves. EVA foam makes backpacks more comfortable to carry.

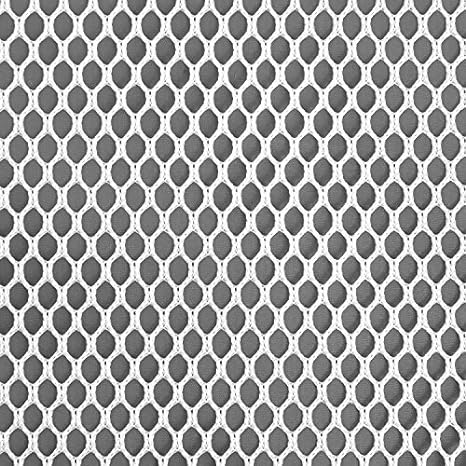

Mesh Fabric

Air mesh fabrics improve ventilation and breathability. Mesh linings help reduce sweat when a backpack is worn against your back. Mesh pockets provide easy visibility of contents.

TPU (Thermoplastic Polyurethane) Films

TPU films add significant waterproofing when used as a backing layer. Laminating TPU to a fabric like backpack nylon creates a fully waterproof material that still looks and feels like a traditional textile.

How are Backpacks Made?

While individual backpack designs vary, the basic construction process follows the same basic steps:

Step 1: Design and Prototyping

The first step in the construction of a backpack is design planning including conceptual sketches and physical prototypes. Multiple design revisions are common to evaluate features like fit, comfort, capacity, and aesthetics.

Step 2: Material Selection

Once the design is finalized, appropriate fabrics are selected for the outer shell, lining, straps, and body of the bag depending on the use of the particular bag. Heavier abrasion-prone areas often get reinforced materials as discussed above.

Step 3: Creating Patterns

Fabric patterns are created based on the final backpack measurements. Computer-aided design programs precisely model patterns to minimize waste, time, and cost.

Step 4: Cutting the Fabric

Patterns are laid out to maximize material utilization. Fabric layers are precisely cut using automated cutters or manual dies.

Step 5: Assembling the Components

Individual fabric pieces are joined to create full components like the main body, front pocket panel, bottom, etc. Sewing and/or bonding creates 3D structured shapes.

Step 6: Sewing the Pieces Together

Assembled components are sewn together to form a finished shell. The frame, straps, and interior accessories are also installed at this stage.

Step 7: Adding Zippers and Fasteners

Zippers, buckles, clasps, and other closure hardware are sewn in place for access and adjustability.

Step 8: Attaching the Straps

Padded shoulder straps are firmly sewn to the top corners of the pack. Waist belts, sternum straps, and other carry straps are attached.

Step 9: Final Inspection and Detailing

Every backpack undergoes thorough inspection looking for any flaws or defects. Some of the bags also go through durability tests to ensure lasting quality. Any issues are repaired before packaging.

Step 10: Quality Control

Backpacks may go through additional random inspections to confirm quality standards are met consistently.

Step 11: Packaging

After passing inspection, backpacks are tagged and bagged for retail sale. Hanging tags, instructions, and warranty cards are attached.

Step 12: Distribution

Finished backpacks are shipped in bulk to distribution centers, then on to retail stores or directly to consumers (in the case of online sales).

What is the Best Fabric to Make a Backpack?

With so many materials and choices, what is the best choice of fabric for backpacks? Here are a few tips that can help you in choosing:

- For durability, abrasion resistance, and strength, nylon and Cordura are top choices. Heavier pack cloth or canvas may also work.

- To waterproof a backpack, look for a TPU film-laminated fabric or silicone/PU coating.

- For ultralight travel, ripstop nylon saves weight without sacrificing strength.

- Leather and waxed canvas have unbeatable vintage style and luxury appeal.

- Breathable mesh linings make a backpack more comfortable to wear.

- Look for reinforced fabrics and panels on abrasion-prone areas like the bottom and side pockets if you’re taking your backpack on a difficult journey.

There is no single best material for every user, the material will always depend on the intended use of the backpack. Consider your personal needs for strength, weather resistance, style preferences, and budget. And don’t forget comfort – padded, breathable straps prevent sore shoulders.

How to Choose the Right Backpack Fabric

Keep these tips in mind when selecting a backpack material:

- Backpack nylon offers the best blend of strength, weight, and cost for general use. It’s a jack-of-all-trades backpack fabric.

- Canvas has vintage appeal but it’s heavier and not waterproof. Waxed canvas adds weatherproofing.

- Polyester works well for basic school and business backpacks at an affordable price point.

- Look for Cordura on high-stress areas like side and bottom panels if you want maximum abrasion resistance.

- Ripstop nylon saves weight without sacrificing durability and tear strength. Great for hiking.

- Leather backpacks have an unbeatable style but require more maintenance.

- A TPU film backing creates a fully waterproof fabric that looks and feels like a textile.

- Mesh-lined pockets and padding improve breathability and comfort, preventing that sweaty back feeling.

What Should I Look for When Buying a Backpack?

- Look for sturdy zippers that won’t fail when overloaded. Heavy-duty backpacks usually have molded zippers, you could look for waterproof zippers as metallic zippers tend to corrode in moist conditions.

- Padding on shoulder straps, back panel, and hip belt for comfort.

- Suspension system to stabilize load and transfer weight to hips.

- The Sternum strap stabilizes shoulder straps and prevents chafing

- Mesh backing and padded air channels enhance ventilation

- Multiple compartments and pockets to stay organized

- Hydration reservoir sleeve if you bike or hike

- Rain cover included or available as an add-on accessory

- Laptop sleeve for securely carrying your computer

- Reflective strips and gear loops for cycling safety

- Burly fabrics on high-wear areas like the base and side pockets

- Compression straps to stabilize contents

Prioritize the features that matter most to your planned backpack use. A streamlined pack for urban commuting has different requirements than a fully loaded trekking bag for multi-day hikes.

Our Top 5 Backpack Recommendations

Here are five of our top-rated backpack models here at Outback Outfitters:

1. American Tactical Rukx Discrete Business Bag

The American Tactical Rukx Discrete Business Bag is an ideal choice for anyone who wants to conceal and carry their defensive pistol on daily errands or during their work commute.

Law enforcement, private security, and civilians with concealed carry permits can discretely arm themselves without attracting attention. The ordinary business bag exterior hides the dedicated CCW compartment inside.

Key Features

- Discreet concealed carry pistol pocket

- 15″ wide x 11″ high interior dimensions

- Black 500D nylon exterior

- Comfortable top carry handle and shoulder strap

- Looks like an ordinary business or mailbag

- Safely and discreetly conceal and carry your EDC pistol

2. Allen Intercept Tactical Pack

The Allen Intercept Tactical Pack is ideal for military, law enforcement, security teams, and tactical enthusiasts seeking a rugged 41L capacity pack with MOLLE webbing and durable EnduraFabric construction. This versatile tactical pack provides extensive organization, hydration compatibility, and carrying comfort for demanding missions or everyday use.

Key Features

- 2500 cubic inch (41L) capacity

- Hydration reservoir compatible

- Rugged EnduraFabric construction

- Internal organizer compartments

- External MOLLE web system

- 18.5″ x 16″ x 10″ dimensions

3. Bfm 100oz-Mil-Spec-Crux

With 100oz hydration capacity and 47L storage, the BFM Mil Spec Crux hydration pack provides high-volume water reserves and cargo space ideal for extended missions. Its adjustable Futura harness custom fits various torso lengths and plate carriers for all-day load-carrying comfort.

Key Features

- 100oz (3L) hydration capacity

- 47L cargo capacity

- Futura harness adjusts to torso length

- Accommodates external plate carriers

- 4 zippered main compartment access points

- Whole clamshell opening for access to gear

- Adjustable sternum strap

- The modified reservoir valve gives 25% more water per sip

4. G-Outdoors, Inc., Handgunner, Backpack, Black, Sof

The G-Outdoors Handgunner Backpack is an ideal concealed carry case for transporting handguns, mags, ammo, and accessories discretely to the range in one package.

Key Features:

- Lockable handgun case

- Storage for 12 mags

- Ammo and accessory organization

- Waterproof pull-out cover

- Sliding cradle for access

- Discreet soft case design

5. Elite 3 Day Backpack

Designed for everyday carry the Elite 3 Day Backpack provides extensive storage with customizable MOLLE webbing and durability.

Key Features:

- Large main compartment with rigid support board

- Padded laptop and tablet sleeves

- Hydration compatible

- Air mesh back panel and shoulder straps

- MOLLE webbing for attaching pouches

- Side cinch straps for longer items

- Zippered front organizer pocket

- Attached rain fly included

Conclusion

Nylon, polyester, canvas, and cotton backpacks continue to be popular backpack options among users for good reason. Each provides versatility at an affordable price point. Bringing in protective elements like TPU coatings or Cordura reinforcements increases their utility for heavy-duty use.

No matter your planned activities, there will be a backpack fabric that will ideally suit your needs. Follow our tips in this guide to select a long-lasting pack that will keep you organized and make carrying more comfortable. The right fabric will help you get the most out of every adventure. Take stock of your carrying needs and style preferences first. Then consider backpack materials that offer the right blend of weather protection, capacity, durability, and comfort.

Frequently Asked Questions

How much weight can a backpack hold?

Backpack weight capacity depends on the size, materials, and construction. Typical capacities are:

Daypack: Under 30L – Good for under 20 lbs

Hiking pack: 30-50L – Can carry 20-35 lbs comfortably

Backpacking pack: 50-80L – Can handle 35-60 lbs or more

Expedition pack: 80L+ – Built to carry 60+ lb heavy loads

What are backpack straps made of?

Backpack straps are usually constructed of multilayer reinforced webbing or belting material. This creates strong, load-bearing straps.

What color backpack should I get?

The choice comes down to your tastes and planned uses but generally bright colors are great for high visibility. Black backpacks are well-suited for business and travel. Earthy tones blend well into natural environments.

What material is used for school bags?

Nylon and polyester are the most common school backpack fabrics, typically with a polyester lining. These synthetic fabrics resist moisture, abrasion, and daily wear and tear. Vinyl/PVC backpacks are inexpensive but less durable.

Is polyester a good backpack material?

Polyester is one of the best backpack materials due to its affordability, durability, and weather resistance. Polyester tends to be more fade-resistant than nylon. PU coatings or TPU laminates add waterproofing for wet environments.